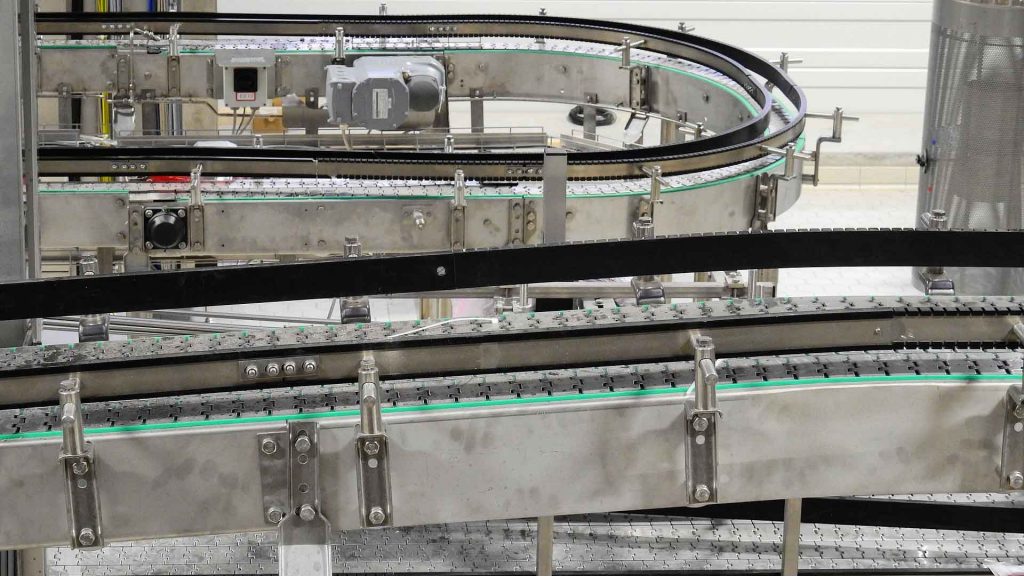

A conveyor belt works as a medium of belt conveyor solutions. Conveyor systems have many types and the conveyor belt is one of them. An inclined cleated belt conveyor is a type of conveyor belt. Belt conveyor systems usually have two or more pulleys plus an endless loop of carrying medium. Conveyor belts are used to move things, e.g. big boxes, large objects, or a large volume of agricultural materials like sand, ore, grain, wheat, salt, sugar, etc.

Since belt conveyors are versatile and the least expensive, they are the most commonly used powered conveyors. They are made with curved sections and its main use is tapered rollers and curved belting so that objects can be conveyed around in a corner. This particular type of conveyor system is most used in postal sorting offices and airport baggage handling systems. We discuss the advantages of inclined conveyors below.

Excellent for Moving Large Items

An inclined cleated belt conveyor is very useful when it comes to moving large objects from one point to the other with ease and efficiency. They can handle loading and unloading for a long time. The inclined cleated belt conveyors that are automated can load and unload heavy items at the desired heights without manual help. Incline conveyors come in both fixed and variable speeds. Some jobs don’t need different moving speed so the owners buy the fixed speed conveyors, others do and their owners buy the variable speed ones.

Move Breakable Items

Since incline conveyors are made with precise angles and automated mechanisms, they can move breakable items with increased safety. This is helpful in manufacturing or transportation areas where there are breakable items that need moving. They are made with rugged, durable, rough top belts for strengthened operations across different floors.

The Reverse Mechanism

The reverse mechanism is one of the most important features of an inclined conveyor. It allows the conveyor to move products both forward and backward. They can operate in a multi-level setting in order to move objects from one floor to the other.

The Noseover Mechanism

Another one of the coolest features of an incline conveyor is its “Noseover” mechanism. This mechanism cannot be found in all incline conveyors, though. They are usually found in high-end incline conveyors. This mechanism allows the objects that are being moved to go to a leveled and horizontal position before they unload. This feature is extremely helpful because it makes sure that objects don’t fall off while being moved from a lower location to an upper one.

Use Less Horsepower

Incline conveyors are not like other conveyors because they operate in a much lesser horsepower than its other counterparts. This saves energy and also saves money. They can be integrated with supporters. As per your need, they can be integrated with both permanent and temporary supporters.

Conclusion

Conveyor belts are very useful for moving items safely and without human interference. They save us a lot of time and energy and keep us safe, too. Inclined conveyor belts are used all the time in manufacturing, transportation, food and beverage, pharmaceutical industries.